Each of these takes over three hours to be readied excluding battery assembly.

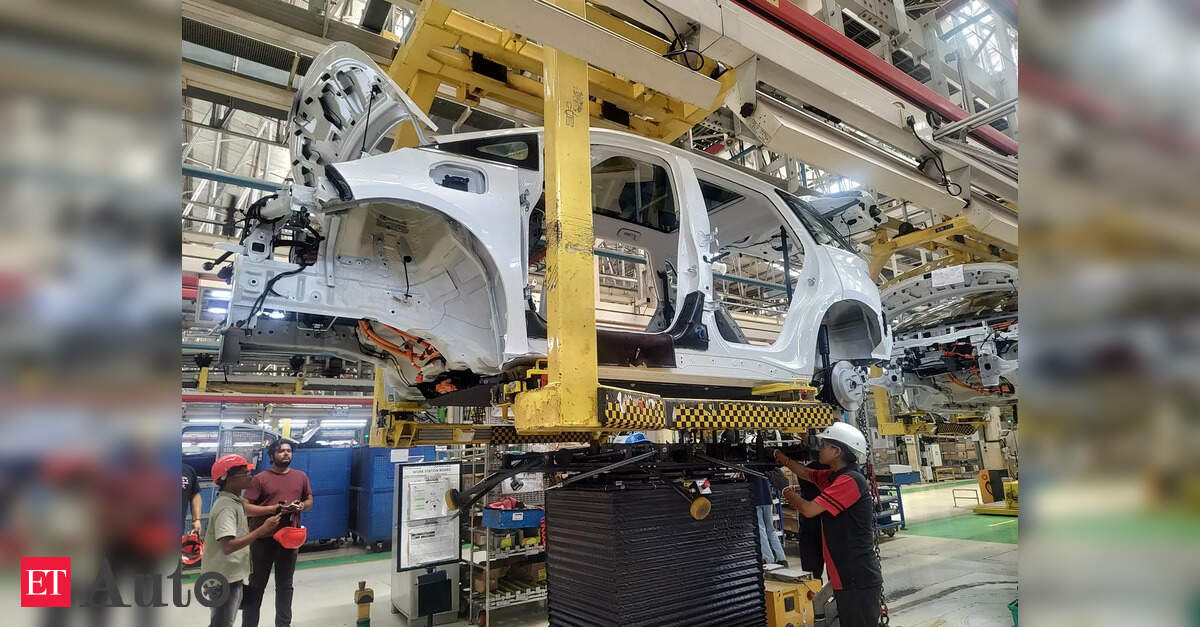

Each of these takes over three hours to be readied excluding battery assembly.Gujarat: From producing the pint-sized Comet to assembling the luxury MG M9 electric vehicle, JSW MG Motor India’s Halol plant in Gujarat has emerged as the centrepiece of the automaker’s diverse product strategy.

Quite unlike the prevailing practice in industry of deploying heavy automation, the company banks on a blend of human skills and Industry 4.0 systems. Placing people at the centre of the manufacturing process is the key for JW MG.

When MG Motor India — as it was earlier known before the JSW Group entered the picture — began its EV roadmap in 2019, it realised that reskilling its workforce was critical. Employees went through crash courses to learn new processes and became skilful enough to handle a multi-model assembly line.

Today, the same line can accommodate vehicles as diverse as the Comet, Windsor, Windsor Pro, ZS EV and Hector. Each of these takes over three hours to be readied excluding battery assembly.

The heart of an EV

Battery assembly remains one of the most crucial operations at the Halol plant. For models like the Comet and Windsor, packs are assembled in-house, while for the ZS EV, batteries are outsourced.

The process itself runs through many intricate stages. It begins with open circuit voltage testing and cell securing with adhesive, followed by spot and laser welding for module assembly. Safety checks, including insulation resistance tests and bus bar connections, ensure electrical integrity before final assembly and validation is carried out through charging and discharging cycles.

Depending on demand, the plant produces 100-145 batteries a day, each requiring around eight hours. Women account for 81 per cent of this section’s workforce and take the lead in inspection and assembly.

To support gender diversity, the company organises family visits and outreach programmes, strengthening both workplace inclusivity and social acceptance. Women comprise 41 per cent of the overall manufacturing workforce at Halol.

EVs take centre stage

JSW MG Motor has a strong presence in India’s EV segment with the Windsor and Windsor Pro leading the sales charts for 11 consecutive months. Last month, the company sold 6,578 vehicles with Windsor dominating volumes. The Comet has also found a niche with first-time buyers seeking an affordable electric option. The company is now preparing for the launch of the M9 luxury EV showcased earlier this year at the Bharat Mobility event. A new general assembly line, GA3, has been allocated exclusively for M9 while the GA2 line handles Comet and Gloster. GA1, meanwhile, continues to be the multi-model line.

Around 80 per cent of manufacturing is dedicated to EVs and there is enough scope at Halol for capacity expansion. “Comet has created a unique proposition by delivering outstanding value for its targeted audience, while Windsor continues to dominate in the CUV segment,” Vinay Raina, Chief Commercial Officer of JSW MG Motor India, told ETAuto earlier.

)